❖ Nectar Design, Engineer, Manufacture & Supply robust construction, high dust collection efficiency Cyclone Separators customized to the desired application. Over the years of experience Nectar have number of successfully operating installations across the spectrum of industries viz iron & steel, food, spices, fine chemicals, carbon black, cement, minerals, petrochemicals, etc

❖ Nectar Cyclones are custom designed to handle gas volumes from few meter cube per hour to several thousand meter cube per hour with high dust collection efficiency at lower pressure drop. Our Cyclones are most economical for the applications involving high operating temperatures.

❖ Depending on the volume of dust laden air or gas to be handled & critical evaluation of the operating & process parameters, we offer unique design configuration of Cyclones to suit the application viz tangential or volute entry, Mono or Single, Twin, Quad, Hexaclone, Octaclone, Outlet to Inlet area ratio, Cylindrical barrel height, Conical height, dust discharge size, dust trap, dipleg requirement & its height, etc

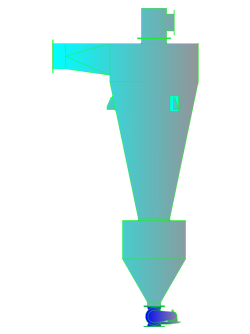

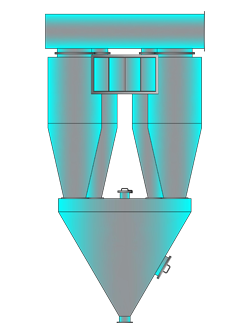

- ✦ Mono or Single Cyclone

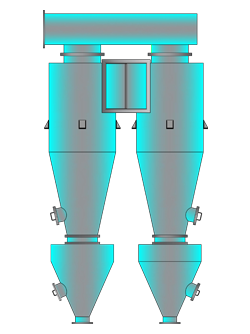

- ✦ Twin Cyclone

- ✦ Quad Cyclone

- ✦ Hexaclone

- ✦ Octaclone

- ✦ Carbon Steel

- ✦ All Stainless Steel Grades

- ✦ High Alloy Steels

- ✦ Refractory or Ceramic lined

- ✦ Abrasive Resistant Material Lined

Single Cyclones are offered for wide range of applications to achieve high dust particle collection efficiency at lower pressure drop. Dust particle collection efficiency & pressure drop are factors of inlet dust laden air or gas volume / inlet velocity (should be constant as much as possible), Specific gravity of dust, inlet dust load, particle size distribution, Operating temperature (should be constant as much as possible), Bulk density of dust, dust physical & chemical characteristics, Cyclone geometry including ratio of outlet to inlet area.

Common applications are in the industries viz iron & steel, Cement, Sawdust, Pelletizing, foundry, fine chemicals including carbon black, detergents & metal oxides, paint & pigment, pharmaceutical, fertilizer, petrochemical, food & spices, etc

Mono or Single Cyclones are generally supplied with following features:

- Tangential or volute inlet

- Wear lining for scroll portion

- Scroll outlet flanged & bolted to cyclone outlet pipe

- Poke hole

- Dust trap welded to cone

- Wear lining for cone bottom portion

- Dip leg

- Dust discharge device

- Refractory or ceramic lining

Twin Cyclones are offered for wide range of applications to achieve high dust particle collection efficiency at lower pressure drop. Dust particle collection efficiency & pressure drop are factors of inlet dust laden air or gas volume / inlet velocity (should be constant as much as possible), Specific gravity of dust, inlet dust load, particle size distribution, Operating temperature (should be constant as much as possible), Bulk density of dust, dust physical & chemical characteristics, Cyclone geometry including ratio of outlet to inlet area.

Common applications are in the industries viz iron & steel, Cement, Sawdust, Pelletizing, foundry, fine chemicals including carbon black, detergents & metal oxides, fertilizer, petrochemical, food & spices etc

Twin Cyclones are generally supplied with following features:

- Tangential or volute inlet

- Wear lining for scroll portion

- Scroll outlets flanged & bolted to cyclone outlet pipes

- Outlet manifold welded to cyclone outlet pipes

- Access / inspection door on outlet manifold

- Common hopper flanged to cones with access / inspection door & poke hole

- Support lugs on hopper

- Wear lining for cone bottom portion

- Turning chain

- Dip leg

- Dust discharge device

- Refractory or ceramic lining

Quad Cyclones are offered for wide range of applications to achieve high dust particle collection efficiency at lower pressure drop. Dust particle collection efficiency & pressure drop are factors of inlet dust laden air or gas volume / inlet velocity (should be constant as much as possible), Specific gravity of dust, inlet dust load, particle size distribution, Operating temperature (should be constant as much as possible), Bulk density of dust, dust physical & chemical characteristics, Cyclone geometry including ratio of outlet to inlet area.

Common applications are in the industries viz iron & steel, Cement, Sawdust, Pelletizing, foundry, fine chemicals including carbon black, detergents & metal oxides, fertilizer, petrochemical, food & spices, etc

Quad Cyclones are generally supplied with following features:

- Tangential or volute inlet

- Wear lining for scroll portion

- Scroll outlets flanged & bolted to cyclone outlet pipes

- Outlet manifold welded to cyclone outlet pipes

- Access / inspection door on outlet manifold

- Common hopper flanged to cones with access / inspection door & poke hole

- Support lugs on hopper

- Wear lining for cone bottom portion

- Turning chain

- Dip leg

- Dust discharge device

- Refractory or ceramic lining

Hexaclones are offered for wide range of applications to achieve high dust particle collection efficiency at lower pressure drop. Dust particle collection efficiency & pressure drop are factors of inlet dust laden air or gas volume / inlet velocity (should be constant as much as possible), Specific gravity of dust, inlet dust load, particle size distribution, Operating temperature (should be constant as much as possible), Bulk density of dust, dust physical & chemical characteristics, Cyclone geometry including ratio of outlet to inlet area.

Common applications are in the industries viz iron & steel, Cement, Sawdust, Pelletizing, foundry, fine chemicals including carbon black, detergents & metal oxides, fertilizer, petrochemical, etc.

Hexaclones are generally supplied with following features:

- Tangential or volute inlet

- Wear lining for scroll portion

- Scroll outlets flanged & bolted to cyclone outlet pipes

- Outlet manifold welded to cyclone outlet pipes

- Access / inspection door on outlet manifold

- Common or twin hopper flanged to cones with access / inspection door & poke hole

- Support lugs on hopper

- Wear lining for cone bottom portion

- Turning chain

- Dip leg

- Dust discharge device

- Refractory or ceramic lining

Octaclones are offered for wide range of applications to achieve high dust particle collection efficiency at lower pressure drop. Dust particle collection efficiency & pressure drop factors are inlet dust laden air or gas volume / inlet velocity (should be constant as much as possible), Specific gravity of dust, inlet dust load, particle size distribution, Operating temperature (should be constant as much as possible), Bulk density of dust, dust physical & chemical characteristics, Cyclone geometry including ratio of outlet to inlet area.

Common applications are in the industries viz iron & steel, Cement, Sawdust, Pelletizing, foundry, fine chemicals including carbon black, detergents & metal oxides, fertilizer, petrochemical, etc

Octaclones are generally supplied with following features:

- Tangential or volute inlet

- Wear lining for scroll portion

- Scroll outlets flanged & bolted to cyclone outlet pipes

- Outlet manifold welded to cyclone outlet pipes

- Access / inspection door on outlet manifold

- Common or twin hopper flanged to cones with access / inspection door & poke hole

- Support lugs on hopper

- Wear lining for cone bottom portion

- Turning chain

- Dip leg

- Dust discharge device

- Refractory or ceramic lining